C2 PROJECT

The many variants of C2s built

The Tender Behind

This page looks at the different designs of tender used with C2s, and considers what our tender should look like when we rebuild it.

The 'Standard' Tender

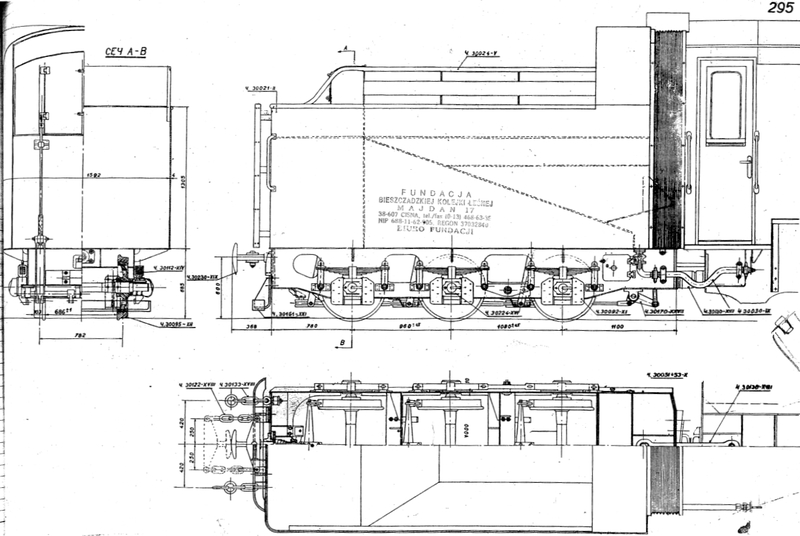

The vast majority of the C2s and their predecessors built in Russia and Eastern Europe had the same design of tender. The tender fitted to the original P24 in 1941 is virtually identical to that supplied with our C2, the last one built in 1988. The only significant changes were from plain bearings to roller bearings, the spring equalising arrangements, and the addition of electric head and tail lamps.

The 'standard' tender is a one-piece fabrication comprising a 6-wheel frame, water tank containing 5200 litres, and space for 2 tonnes of coal. At the front is a half-cab, connected to the loco cab with a canvas corridor connection. The half-cab also contains the handbrake column, shovelling plate and storage lockers. The coal space is the full width and height of the tender, so there is no rearward visibility through or over the tender. Consequently the standard loco cabs have no windows in the backplate.

Tenders built at Harbin carry a stamped aluminium worksplate on the driver's side of the half-cab; this has the technical data for the tender (the loco carries a similar plate with the loco data). The works number for loco and tender is the same.

Loco cab design evolved to become wider over time, but the tender remained unchanged at 1700mm wide. So the P24 tender width closely matches the cab; the Polish KP-4 has a cab 200mm wider while the on the late-build C2s the cab is 500mm wider. One advantage of the wider cab was the ability to see alongside the tender when running backwards, and the later locos have windows in the back of the cab.

Many railways made minor modifications such as plating in the coal rails to retain poor-quality coal. There were also many variations in couplings to suit each railway.

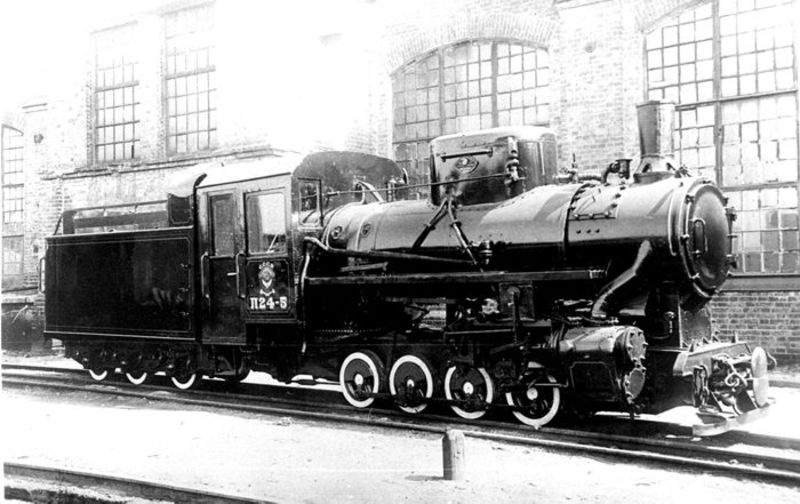

Locomotive P24-5 built by Kolomna Works (8223/1941) (Photo from the collection of L. Moskalev)

Preserved Polish-built KP-4 in Europe: tender a little narrower than the cab (Thanks to the Estonian Narrow Gauge Railway Museum at Lavasaare)

Newly-built or overhauled C2 at Harbin Works in November 1986 showing wider cab with rear windows (Photo: © Mick Pope)

Rear view of two of the Dahuichang C2s in 2005 showing the cab rear window giving a view alongside the tender (Photo: © Darryl K Bond)

Our loco with its original narrower cab, not much wider than the tender. We will make a new cab to a similar narrow profile to fit through the FR tunnels (Photo: © Rob Dickinson)

Our loco after rebuilding with a wide cab. The tender worksplate is visible above the capacity lettering. Note that the coal rails were cut away on this side to make coaling easier (Photo: © Dudley Hubbard)

GA drawing of the 'Standard' tender, from the Polish KP-4 drawings we have. Our tender differs only in minor details: roller bearing axleboxes, electric lighting, couplings and the shape of the ladder.

Variants on the Standard Tender

The C2s at the well-known Shibanxi railway had some standard tenders with a curious modification: the tender body was raised a few inches higher. These locos also have an open-back cab without corridor connections, and the cab entrance through the gap between cab and tender, rather than a cabside door. While many of these locos are still in use, they are now fitted with bogie tenders; one 6-wheel tender currently survives at the museum at Mifengyan.

Also illustrated are two of the more major modifications to suit local requirements at other railways.

Side view of the preseved Shibanxi tender showing the raised body of the six-wheel tender (Photo: © Paul Molyneux-Berry)

Rear view of two locos at Shixi showing the spacers under the raised bodies of the six-wheel tenders (Photo: © Paul Molyneux-Berry)

A tender with the rear part reduced to the height of the water tank top, at Taiyuan Steelworks in 1981 (Photo: © Robin Gibbons)

Two tenders with generators recently added to the rear, at the Yujian Railway in 2016. This railway is being rejuvenated as a tourist line and has collected locos and rolling stock from other closed lines: '001' is from Yinghao. (from www.kii762mm.com/modules/pico/index.php?cat_id=213)

The 'Long-Distance' Tender

Some C2s ran with a larger bogie tender, which appears to have been a standard design supplied to several railways throughout China. Railways using this type of tender included many forestry railways in North-Eastern China, numerous local railways in Henan in the centre of the country, and Rongshan in the South-West. The tenders illustrated below carry Harbin-style stamped works plates just behind the cab.

In appearance this has similar style to a stretched 6-wheel version, but has slab sides instead of coal rails. It is substantially longer, carrying 9000 litres of water and 4 tonnes of coal; almost twice as much as the 6-wheel tender. Some C2s seem to have been supplied new with this tender, but most of these tenders were probably built to accompany existing locos.

Structurally the tank rests on a separate frame (in contrast to the 6-wheel tender). The examples I have seen at Rongshan were not fitted with a handbrake, but both loco and tender were air braked.

Harbin 203 at Suiling in 1992: a clean C2 and bogie tender probably recently overhauled. (Photo: © David Kitching)

Rear ¾ view of Harbin 211 at Rongshan in 2014 showing the tender details. At Rongshan, 210 has an identical tender while 218 and 219 have a different design of bogie tender - visible in the background. Of course, their near sisters at Dahuichang 216 and 221 have 6-wheel tenders. (Photo: © Paul Molyneux-Berry)

The Rongshan 'Slope-Back' Tender

These tenders were used at Rongshan in Sichuan province. The two locos fitted with this type of tender are Harbin 218 and 219, sister locos to our 221. None of the photos of Harbin Works in the late 1980s show any non-standard tenders so these may be of local construction. They do not carry formal worksplates but both have March 2001 welded into the rear footsteps - they may represent build or overhaul dates.

The design is essentially a small version of the tender on a standard-gauge SY, and may have been inspired by the SYs operating the branch to Rongshan. Handrails and footsteps provide safe access to the top of the tender. A corridor connection between loco and tender is fitted, but is narrower than normal to fit the front of the coal-space which forms a vestigial half-cab. The cab rear windows are correspondingly wider. This combination of features offers excellent rearward visibility from within the cab.

Structurally the tank rests on a separate frame, which ends flush with the front of the tank. The tank itself is a little wider than the standard design, although still not quite as wide as the modern cabs on these locos. The bogies are very close together, and they are not fitted with a handbrake; however air brakes are fitted to both loco and tender. Coal and water capacity is not known.

Harbin 219 at Rongshan in 2014 showing the tender details in comparison to a standard-gauge SY class. (Photo: © Paul Molyneux-Berry)

Shunter's view (Photo: © Paul M-B)

Harbin 219 from the front, showing the relatively wide tender tank. (Photo: © Paul Molyneux-Berry)

Broadside view of the tender on Harbin 219, showing the bogies very close together (Photo: © Paul Molyneux-Berry)

The Pengzhou 'Slope-Back' Tender

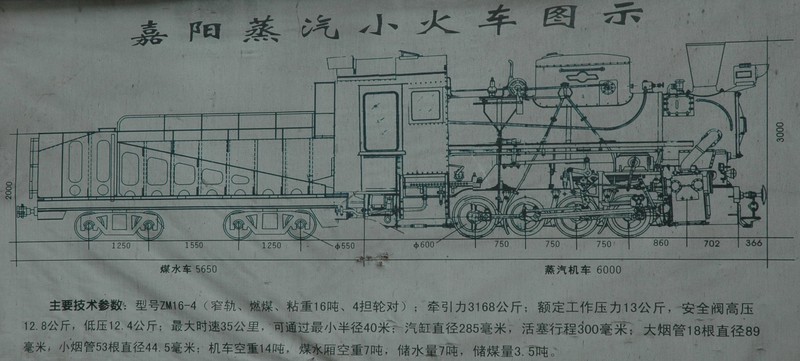

These tenders were used at Pengzhou in Sichuan province; they may have been locally constructed or modified to suit particular operating conditions. These tenders are superficially similar in shape and size to the Rongshan design, but differ in several significant ways.

Structurally the tank rests on a separate frame which is longer than the Rongshan design; it extends forwards of the tank, providing a cab entrance for these locos with open-backed cabs and no doors. The tank appears to have similar dimensions but may be a little longer. The additional frame length is most obvious when looking at the space between the bogies. The coal space is narrow like the Rongshan design, but there is no corridor connection. Coal capacity was 2.5 tonnes, and 10,000 litres of water could be carried.

The tender of a 28-tonne loco at Pengzhou. The locos here were to the same basic design as C2s, but carried worksplates from the Chengdu Railway Machinery Factory and were classified ZM16-4. Note that the back of the cab is mostly open, with a window in the small panel behind the driver. (Photo: © Robin Gibbons)

Rear ¾ view of a Pengzhou tender (DVD capture: © John Raby)

Rearward view from the cab of a Pengzhou loco, showing the clear visibility (DVD capture: © John Raby)

The Shibanxi 'Slope-Back' Tender

Around 2007, two locos from the Pengzhou line were transferred to the Jiayang Coal Railway at Shixi in Sichuan province - the railway commonly known as Shibanxi. It appears that the workshops at Shibanxi were inspired by the bogie tenders used at Pengzhou and decided to build new tenders for their entire fleet. These replaced the earlier 6-wheel types and are superficially similar to the tenders at Pengzhou in both shape and dimensions. They were constructed in the workshops at Shixi from 2008, and some have their build date recorded in weld bead on the top walkways.

Structurally the tank rests on a separate frame, which is the full width of the tender and extends forwards of the tank, providing a cab entrance for these locos with open-backed cabs and no doors. Unlike the Rongshan and Pengzhou tenders, the front part of the tank is similar to the standard tenders, with a small half-cab and full width coal space. The sloping rear part echoes the shape of the Pengzhou tenders, but there is no handrail and no rearward visibility past the coal-space. The rear bogie is also mounted further forward than on the Pengzhou tenders, though the bogie spacing remains greater than the Rongshan type. Water capacity is 7000 litres, with space for 3.5 tonnes of coal.

A tender takes shape in the gloom of Shixi workshops in 2013 (Photo: © Paul Molyneux-Berry)

Rear view of three Shibanxi tenders in 2013, showing some detail differences (Photo: © Paul Molyneux-Berry

New-build loco 16 and slope-back tender at Shibanxi in 2013 (Photo: © Paul Molyneux-Berry)

Side elevation drawing of a loco and tender displayed in the workshops at Shixi on the Shibanxi railway. Note that the actual tenders have slightly different proportions to the drawing. (Photo: © Paul Molyneux-Berry)

Comparison of Tender Profiles

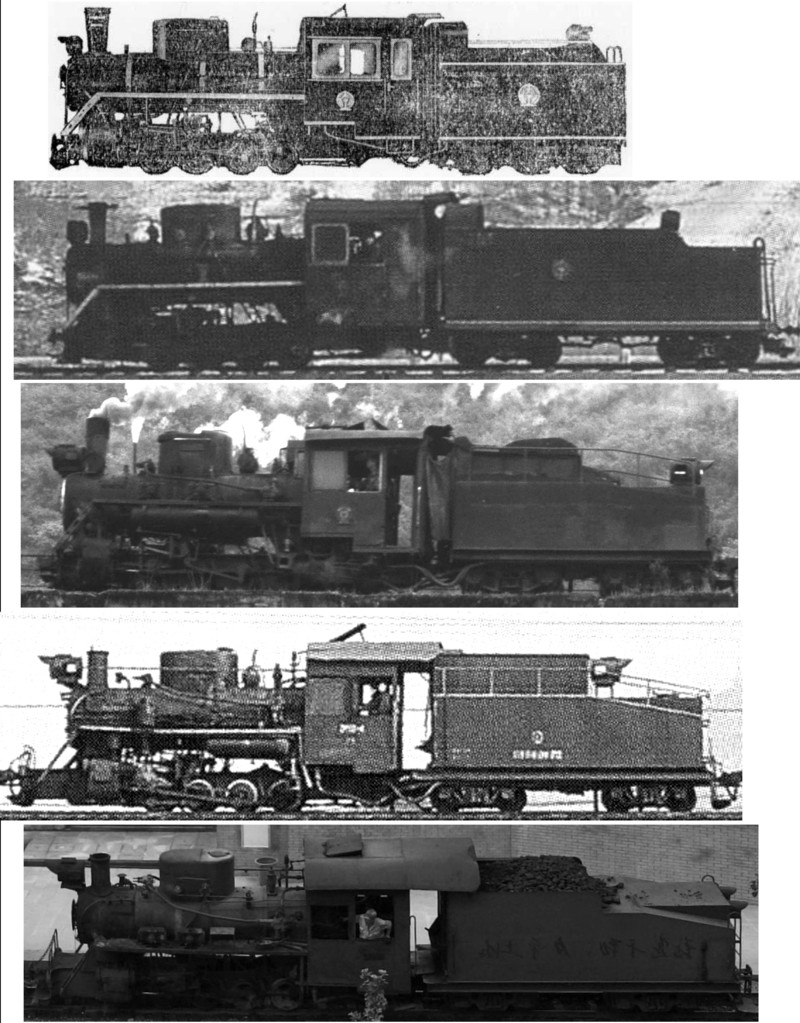

These photos show a side view of each of the tender types discussed, to illustrate the differences. As far as possible the photos are reproduced to the same scale, with the chimney centreline and cab front aligned.

Note that the Pengzhou and Shibanxi locos have a shorter, open-backed cab with entry via a gap between cab and tender. On these tenders the frame protrudes forward of the tank, and the leading tender wheelset is under the front of the tank. In contrast the other locos have a longer cab with side cab access door and a corridor connection to the tender. On these tenders the frame ends flush with the front of the tank, and the leading tender wheelset is set back from the front of the tank. Consequently the bogies of the Rongshan tender are much closer together than the Pengzhou tender, despite a similar length of tank.

Top: Standard Tender, Second: Long Distance Tender, Third: Rongshan Slope-Back, Fourth: Pengzhou Slope-Back, Bottom: Shibanxi Slope-Back

Bogies

A variety of bogie types seem to have been used on the bogie tenders. The 'Long Distance' tenders all appear to have been built with the same time of cast 3-piece bogie with roller bearings. Other tender types may have been locally-built using whatever type of bogie was available. Five different bogie designs used on the bogie tenders are illustrated below. All the bogies are of '3-piece' design but there is variation in the sideframes, suspension and axleboxes.

Long Distance Tender Bogie (Photo: © Paul Molyneux-Berry)

Rongshan Slope-Back Tender Bogie (Photo: © Paul Molyneux-Berry)

Pengzhou Slope-Back Tender Bogie (Photo: © Robin Gibbons)

Shibanxi Slope-Back Tender Bogie: Type 1 (Photo: © Paul Molyneux-Berry)

Shibanxi Slope-Back Tender Bogie: Type 2 (Photo: © Paul Molyneux-Berry)

Tender Worksplates

C2s built at Harbin mostly carried 4 worksplates of 3 types; many of these seem to have been removed in later life.

Each side of the loco dome was a cast aluminium plate, reading 'Harbin Forest Machinery Factory'. The example we have has been painted both red and black in the past.

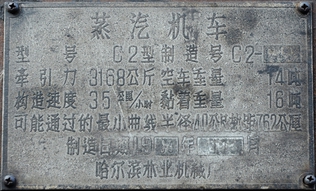

On the driver's side of the cab was a small black-enamelled aluminium plate, similar in style to that traditionally used on electrical equipment. In etched lettering, this defines the basic technical characteristics of the loco (class, tractive effort, empty and laden weight, maximum speed, minimum curve radius, track gauge and manufacturer). Blank spaces are provided for the works number to be stamped in, along with the year and month of construction.

On the driver's side of the tender half-cab was a similar aluminium plate. This defines the basic technical characteristics of the tender (class, coal and water capacity, empty and laden weight, and manufacturer). As for the cabside plate, blank spaces are provided for the works number to be stamped in, along with the year and month of construction.

For locos with 'standard' tenders, it appears that the loco and tender would normally carry the same works number.

Dome worksplate on Harbin 211 of November 1983 at Rongshan (Photo: © Paul Molyneux-Berry)

Photo showing the position of loco cabside and tender worksplates: Harbin 211 at Rongshan in 2014 (Photo: © Paul Molyneux-Berry)

Loco cabside worksplate from Harbin 211 of November 1983 (Photo: © Paul Molyneux-Berry)

'Standard' tender worksplate from our tender: Harbin 221 of January 1988 (Enhanced scan: © Paul Molyneux-Berry)

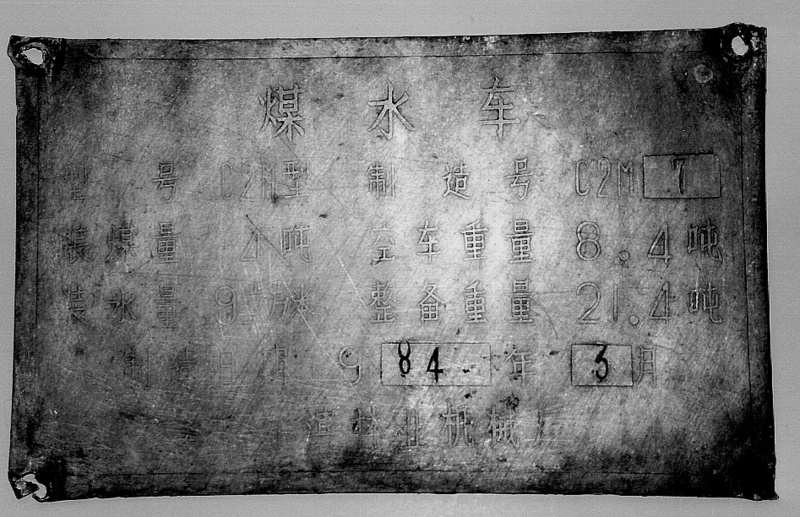

It appears that the 'Long Distance' tenders were numbered in a separate series, not matching contemporary locos. The bogie tender worksplates carried the designation 'C2M' and were built at Harbin.

Early examples seen include tender works numbers 5 and 6 of November 1983 (accompanying Rongshan 210 and 211 of November 1983) and 7 (unknown loco, dated March 1984). Later examples include works numbers 41 (June 1987), 44 (July 1987) and 51 (November 1987); with few new C2 locos being built at this time, these later tenders may have been built to accompany an existing loco, perhaps as the forestry lines became longer and a greater capacity was needed.

Worksplate from a 'long-distance' tender, number 7 built in March 1984. (from http://www.justaclickago.com/1%20SUMMER%202014/G%20301%20to%20350.htm)

Worksplate from a Harbin 'long-distance' tender described as 'C2M', number 51 built in November 1987. (from http://www.justaclickago.com/1%20SUMMER%202014/G%20301%20to%20350.htm)

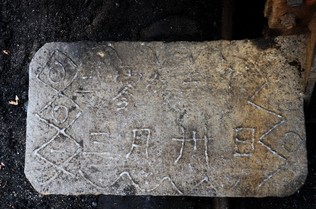

We have not observed formal worksplates on any of the slope-back tenders. However, it appears to have been common practice to create a non-slip tread on footsteps and walkways by writing in weld bead, and these words often include dates (most likely the dates of build or repair).

Shibanxi tender number 14, showing an August 2008 build date recorded in weld bead on the sloping rear section. The Mandarin wording on the right-hand side translates as 'Transport Department', presumably of the Jiayang Coal Company that owns this railway. (Photo: © Paul Molyneux-Berry, thanks to Yunshi Zhao for the translation)

2001-03-08 date on the tender footstep of Harbin 218 at Rongshan (Photo: © Paul Molyneux-Berry)

2001-03-30 date on the tender footsteps of Harbin 219 at Rongshan, written in traditional Mandarin (Photo: © Paul Molyneux-Berry, thanks to Yunshi Zhao for the translation)

Plans for Our Tender

Our C2 was built with a late-pattern 'Standard' 6-wheel tender; the tank of this was in poor condition when we bought it and has since rotted right through in several places. Together with re-gauging the wheelsets and fitting completely different drawgear and brakes, most of our tender will be brand new. This gives us considerable freedom of design - what should it look like?

An early decision we made was to retain a 6-wheel tender. The extra capacity of a bogie tender is not needed on the Ff&WHR, and the additional length and weight is a disadvantage. Also, we've got the frames, springs and wheelsets as a good starting point. So work to date has focused on refurbishing these components.

Another decision we have made is that the tank should be structurally separate from the frames. This approach is used on most Ff&WHR locos, and has many construction and maintenance advantages. A large profile-cut plate will be welded to the top of the frames to give them the strength they previously derived from the tank base. The tank will be a separate water-tight vessel bolted to the frames.

To fit within the FR kinematic envelope, we need to fit a narrow cab, similar in dimensions to the original Russian design but mounted a little lower to ease clearances at the cantrail. If we were to replicate the standard design of tender, there would be no rearward visibility from within the cab. On the FR, the clearance to the scenery is often very small and Wales has plenty of weather, so having to lean out of the cab to see the line ahead isn't really acceptable.

The Rongshan or Pengzhou designs are therefore attractive, as they both have excellent rearward visibility. The key difference between them is in the cab access arrangements and the ability to keep out the inclement weather - the Rongshan tender with corridor connection suits a fully enclosed cab (as fitted to our #4 originally) and again is preferable in the Welsh weather conditions.

So one possibility is to design a tender similar in shape to the Rongshan design, but slightly scaled down to suit our 6-wheel frame. Styling could take design cues from the standard 6-wheel tender.

Another option is to use the standard tender design as a basis, but lower and widen the tank a little and provide a line of sight through the half-cab and over the coal bunker.

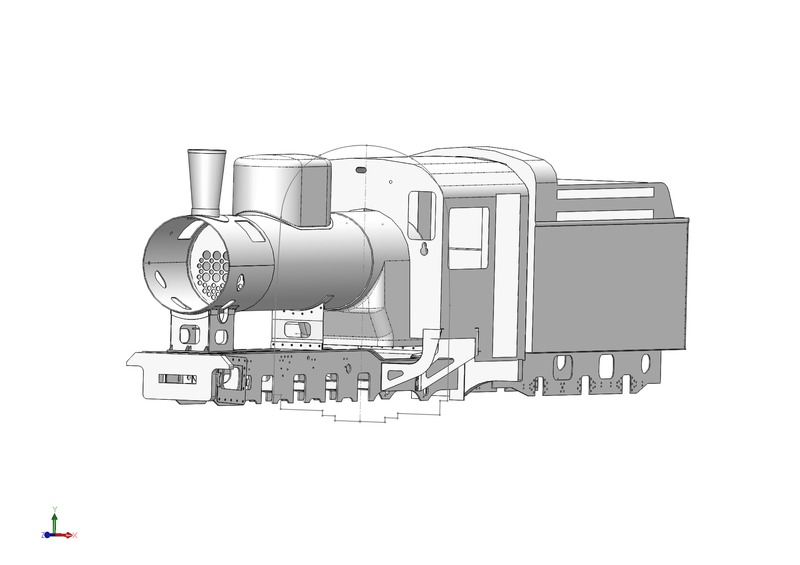

We're intending to design these in 3D CAD so that we can visualise them from all angles before making a start on construction. Watch this space for emerging designs…

Caption: View of the developing 3D model of our C2, showing the currently proposed cab shape which will fit the FR loading gauge, and an unmodified 'standard' tender. (Photo: © Paul Turner)

Acknowlegements

Thanks to all that provided photographs for this page, and to John Athersuch, Robin Gibbons and Jeff Lanham for contributions to the text and information presented.