C2 PROJECT

History of C2 worked railways

The Railway at Dahuichang

Overview of the Quarry and Factory History

The Dahuichang Limestone Railway was a short, double-track line which linked a quarry to a lime, chemical and brick factory. Being only 1.5km (1 mile) long, it is surprising that a railway was used instead of a conveyor belt, but this may be indicative of the technology available in China when the line was built.

Although we have been unable to find a detailed history book specifically about the Dahuichang factory, information has been gathered from numerous Chinese sources covering the Beijing Building Materials Bureau, Shijingshan steelworks and its later owner Shougang, the Fengtai District and Dahuichang Village, and from the locomotive drawings we copied at Dahuichang. These all correlate quite well!

Limestone has been quarried at Dahuichang on a small scale for centuries. The present limestone quarry at Dahuichang was built in 1953, and the railway opened about 1954. This was comparatively early for industrialisation in the People's Republic of China; pre-dating the ‘Great Leap Forward’ period which saw a huge expansion of industries and narrow-gauge railways. Initially the limestone was used in the blast furnaces of the Shijingshan Steelworks, and a few undated locomotive drawings seen at Dahuichang were titled Shijingshan Iron & Steel Company Limestone Mine 石景山钢铁公司石灰石矿.

The finer limestone particles were unsuitable for steelmaking, so in 1956 a plant was built at Dahuichang to use these for other purposes. In that year the Beijing Sand and Stone Factory 北京市砂石厂 and the Beijing Limestone Factory 北京市灰石厂 were built and merged with the quarrying operation. The combined company was part of the Beijing Bureau of Building Materials and the factory name was Beijing City Limestone Plant 北京市灰石厂. The locomotive drawings seen at Dahuichang dated 1961-1963 carried this title. In October 1964 the nearby Fengtai Lime Plant was absorbed too.

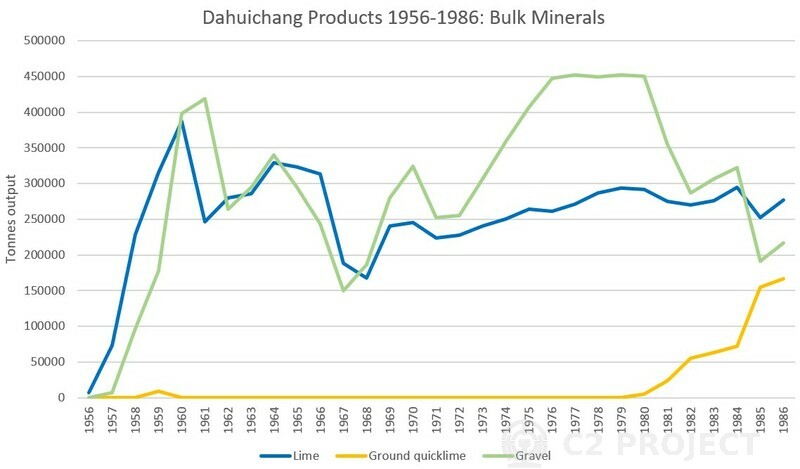

Initially the major products were limestone gravel and lime, typically around 300,000 tonnes of each annually. Although Dahuichang was no longer directly controlled by the Shijingshan Iron & Steel Company, most of these bulk minerals were still supplied direct to the steelworks at Shijingshan.

Bulk mineral product output from Dahuichang: 1956 to 1985

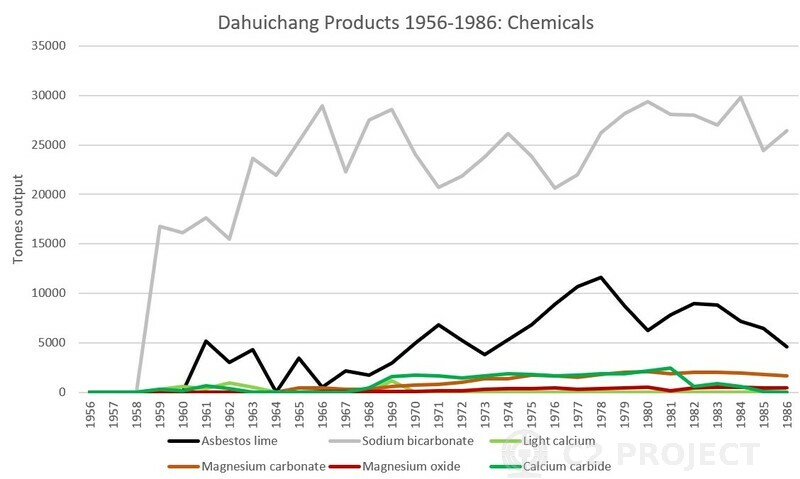

By 1959 the factory was diversifying into chemical production. The production of lime from limestone creates Carbon Dioxide as a by-product, and in an early form of 'carbon capture' this was used to make Sodium Bicarbonate (baking soda) and Calcium Carbide (for lighting and industrial purposes). A product described as 'Asbestos Lime' was also produced.

During the Cultural Revolution in 1965-1970 there was much re-organisation and the Dahuichang factory became a subsidiary of the Beijing Limestone Factory named 灰砂石总厂直属车间. The locomotive drawings seen at Dahuichang dated 1969 carried the title 北京市灰砂石总厂 (Beijing Limestone Factory).

There was also some disruption to production during the Cultural Revolution period. However, in 1971 it regained its original name Beijing Limestone Factory 北京市灰石厂 as part of the Beijing Bureau of Building Materials. During this period the range of chemical products was expanded to include Magnesium Carbonate and Magnesium Oxide. However, Sodium Bicarbonate remained the dominant chemical product with an annual output around 25,000 tonnes. Most of this was food grade, with smaller quantities for pharmaceutical and industrial purposes. Maybe you have eaten a cake made with Dahuichang baking soda!

Chemical product output from Dahuichang: 1956 to 1985

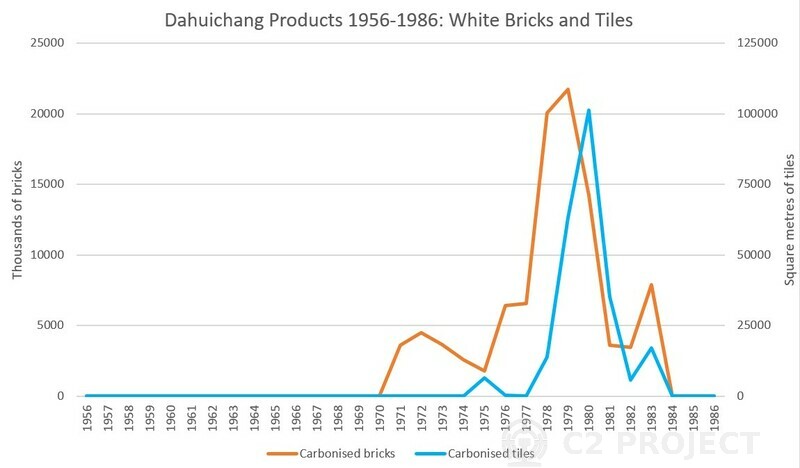

In the late 1960s, a brick factory was added; this combined limestone, lime and water into bricks which were baked in the carbon-dioxide-rich exhaust gases from the lime kilns. This technique reduces the CO2 emissions of a cement factory while producing a valuable by-product, and has recently been considered for wider use to reduce the environmental impact of cement manufacture. The resulting pale coloured bricks were used for important buildings including some of the embassies in Beijing, and later the factory made tiles using the same process.

White brick and tile output from Dahuichang: 1956 to 1985

In the early 1980s the production focus changed somewhat. Gravel production reduced but was balanced by an increase in ground quicklime so the total of the bulk minerals remained similar. Most of these were still supplied direct to the steelworks at Shijingshan, by now part of the Shougang conglomerate. Production of white bricks and tiles ceased in 1983, and calcium carbide production stopped in 1984. In 1985, the factory was renamed Beijing Building Material Chemical Factory 北京市建材化工厂, still part of the Beijing Building Materials Bureau.

From 1989, concerns were raised about the environmental impact of the quarry and industry. Shockwaves from blasting were damaging nearby ancient temples, while dust and fumes were causing serious air pollution in the region.

In 1992, the quarry and factory were incorporated into Shougang, becoming the Beijing Shougang Building Material Chemical Factory 北京首钢建材化工厂. This re-united the quarry and lime works with its major customer (as had originally been the case). The chemical products side of the business was spun off as a joint venture with capital from Hong Kong, becoming the Beijing Lingyun Building Material Chemical Co. Ltd. 北京凌云建材化工厂.

However, in 1991 limitations were placed on the blasting operations at Dahuichang quarry, which became gradually stricter through the decade. This forced a significant reduction in the output from the quarry and the plants. The total staff employed at Dahuichang fell 70% from 2500 to 700, and the annual Sodium Bicarbonate production fell by a similar percentage to 6,000 tonnes. The lime out output and railway traffic probably fell by a similar amount: by 1997 the railway was reduced to operating a single shift in the afternoon.

With the 2008 Beijing Olympics on the horizon, the Chinese government implemented policies to clean up Beijing’s atmosphere. A consequence of this was the complete closure of Shijingshan steelworks in 2005 with its activities being moved to Tangshan. With its major steelworks customer gone and further restrictions on quarrying, the quarry and railway closed in 2005.

The Beijing Lingyun Building Material Chemical Co. Ltd continued to produce Sodium Bicarbonate using limestone brought in from elsewhere. However, what had once been the factory's major product (lime) was now a by-product without a ready market. Without integration with the steelworks, this was not a viable operation and the factory at Dahuichang gradually wound down with final closure in 2013. Sodium Bicarbonate production has been moved to the city of Handan, and the company has been rebranded as Xinxing Lingyun Pharmaceutical Chemical Co. Ltd. 新兴凌云医药化工有限公司 .

After closure of the quarry and railway in 2005, some items were quickly scrapped or sold, including the wagons, tipplers, and locomotives 1 and 4 (we bought 4, and our contract was with Beijing Shougang Building Material Chemical Factory 北京首钢建材化工厂). However, the remaining equipment was simply abandoned, with most of the factory and railway buildings remaining in existence in 2019. Many of the rails are still in place although overgrown, and remarkably locomotives 2 and 3 remain intact in a securely locked loco shed. However, the latest Google maps appear to show new developments at the quarry end of the line and this may all disappear under the march of progress fairly soon.

You can look at the current situation for yourself and compare between 2005 (around the time of the last railway operations) and now.Dahuichang Interactive Map.

Operations and Track Plan

(to be completed)