C2 PROJECT

The C2 Project Official Website

Frequently Asked Questions

Visitors to our shed often ask us questions about the loco and the project. Here are a selection of the more popular questions, together with our answers.

A1: Yes. We have already re-gauged the frames and wheelsets to suit the 597mm track gauge on the Ff&WHR. The cylinders, boiler, dome and other boiler fittings are all within the FR loading gauge, so will fit both railways. As purchased, our loco carried the largest variant of cab design and this is unfortunately too large. C2 locos carried a wide variety of cab shapes and we will build a new cab in an appropriate style, but small enough to fit the FR loading gauge.

The Funkey diesel is built to the limits of the FR loading gauge. Seen here in comparison to our C2, note that the C2 is about 6" higher than it will be in service, as it is on accommodation bogies. (Photo: Paul Molyneux-Berry)

A2: No. Although the boiler is mounted high, most of the weight is low down in the frames and wheels. There are no water tanks on the loco, so the dangers of sloshing water are reduced. We have also stiffened the roll suspension, as the loco will not have to cope with track quite as terrible as that on some Chinese lines. Two of the C2 Project Group are professional rail vehicle dynamics engineers and are well-versed in this type of analysis. In Russia, several of the near-identical VP-1 locomotives were built to 600mm gauge and apparently ran successfully. There were even 600mm gauge variants of the larger Px-48 locos which ran in Albania.

A 600mm gauge Px-48 in Albania. These 0-8-0s are the larger cousin of the VP-1 / KP-4 / C2 design. 600mm gauge VP-1s also existed in Russia but we have not found any photos. (Photo: Uwe Bergmann)

A3: Fast enough. Maximum line speed on the Ff&WHR is 20mph, and 18mph is usually sufficient to keep time. The locomotive specification quotes a maximum speed of 35km/h which equates to 22mph. The wheels are 600mm diameter which is similar to the FR's 'Prince'. 'Prince' is 125 years older than our C2, but is still easily capable of 20mph. The C2 has streamlined steam passages and long-travel piston valves, so the steam supply and exhaust should not be 'choked' at speed. C2s regularly run at speeds around 18mph in China.

High speed C2. Paul Molyneux-Berry.

A4: We have calculated the tractive effort, the adhesive weight and the grate area (and other parameters governing the steaming capacity). These indicate that the C2 should be substantially more powerful than an FR 'Lady' (Linda and Blanche) but not quite as powerful as a double Fairlie. Ladies are rated at 8 coaches on the FR, while Fairlies can haul 12. So it's reasonable to assume that the C2 will be capable of keeping time with a 10-coach train on the FR. Most FR trains are 9 or 10 coaches so the C2 would be a 'useful' loco throughout the season. Gradients on the WHR are twice as steep, so the C2 would probably haul 6 coaches, suitable for low season usage. One of the C2 Project members has driven a C2 in China hauling approximately 80 tonnes of coal (approx 8 FR coaches) up gradients of 1:40, at around 15mph.

A C2 hauls 15 loaded wagons of coal on the Shibanxi railway, which has gradients of about 1:40 against the load. 3 hours earlier the photographer had been driving an identical train past here on the previous trip. (Photo: Paul Molyneux-Berry)

A5: We're not sure! The work is done and funded by the owning group of 6 people, with valuable support from a few other regular volunteers. Funds and free time are limited: the project is an enjoyable hobby for us, and by setting artificial deadlines there is a risk that it would become more of a chore. We're making steady progress, and we'd like to see the loco finished in the early 2020s.

A6: Most of it. Two of the reasons for doing the project are for us to improve our skills, and to keep alive the knowledge needed to build and maintain steam locos. The group enjoy the challenges of design, machining and fabrication, and we like learning skills such as white-metalling bearings. However, there are some tasks that we sub-contract elsewhere, usually because we do not have the expertise or the equipment. A good example is the wheelsets: we dismantled the old wheelsets and refurbished the wheel centres ourselves. Wheel tyres were supplied by Railway Wheelset and Brake Ltd, axle material from Lucchini UK, and we rough-machined the axles ourselves. FR Boston Lodge Works staff did the final axle machining, and the wheelsets were assembled by CMS-Cepcor.

C2 Project Group member Andrew, and regular volunteer Chris, hard at work on axles and axlebox components. (Photos: Paul Molyneux-Berry)

A7: There are several ways you can help:

Financially, you can help with a donation, or by purchasing some of our merchandise

We have enjoyed the support of certain companies who have provided parts, materials or services at favourable rates; these have included Railway Wheelset and Brake Ltd , Lucchini UK , Unipart Rail, and Tata Steel. Our friends in Poland restoring a near-identical KP-4 sent us a full set of manufacturing drawings for the loco.

Do you work for an electrical equipment supplier that could refurbish our turbo-generator? Can you give us 'mates rates' on roller bearings?

Do you work for an electrical equipment supplier that could refurbish our turbo-generator? Can you give us 'mates rates' on roller bearings?

Maybe you have some steam loco spare parts tucked away, that would be more at home on a loco? Sounds like a joke but we acquired a C2 whistle and a cabside forestry plate this way, thanks to Rob and John! Top of the wants list is a suitable vacuum ejector, and we'd also like a spare injector of our existing type.

Practically, you might like to become a volunteer on the project. We have several regular volunteers who enjoy working on a project that they can see from start to finish, but would rather not have the financial obligation associated with being part of the owning group. We get together on a regular basis every month, plus occasional additional working parties. PLEASE contact us to discuss this rather than just turning up. New volunteers need to be registered and formally inducted, and we need to organise some appropriate tasks for you.

A8:The loco only worked for about 15 years. Dahuichang was a limestone quarry, and the loco water supply was provided through a treatment plant so the boiler was free of scale when examined, and in very good condition. Over 5000 of these boilers were built so it is a proven design, although there were some subtle variations.

Getting a foreign boiler approved for use in the EU is not an easy matter (and it shouldn't be, because of the risks involved with pressure vessels). We have had some discussions with boiler insurers and have a plan of action for getting the boiler approved. This will address the design, materials, build quality and condition. Already we have carried out a lot of design calculations, and carried out a hydraulic test of the boiler before removing the tubes. We have had a sample of boiler material tested by the Tata Steel labs, which has shown that its chemical and mechanical properties are compliant with the relevant British Standards.

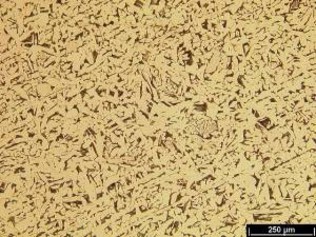

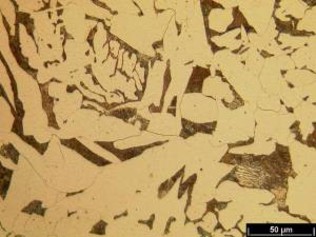

Steel microstructure of our boiler barrel at two magnifications (Photos: Tata Steel)

A9: The C2 Project Group has 6 shareholders, 5 of whom are regular Ffestiniog Railway steam locomotive drivers.

Alan is a Quality Engineer, working in the metal packaging industry.

Andrew is an Operations Engineer in the power generation industry.

David is a Professional Engineer in the rail industry working in vehicle dynamics and gauging.

Jon is a Storage Consultant in the IT industry.

Paul is a Professional Engineer in the rail industry specialising in rail-wheel interaction.

Sam is a Marketing Manager working in the medical sector and is also a Director of the Festiniog Railway Company.

Many other names appear on the news update pages. These are people who, whilst not shareholders, have generously given their time to assist us. Our longest-standing volunteer is Chris, a software engineer for a multinational IT services company. More recently our group of regular volunteers has grown significantly with the addition of another Dave, plus Colin and Matt.

We have adopted the symbol of the Chinese Forestry Railways for our project.

You may be familiar with the logo of the Chinese national railway network: this consists of a flat-bottom rail surrounded by a stylised version of the Mandarin character 'ren': 人, meaning person or people. The combined symbol looks like the front of a steam loco and represents the 'People's Railway'.

The Chinese Forestry Bureau replaced 'ren' with a stylised version of the Mandarin character 'sen', which is used in the phrase for forest: senlin 森林. Cast aluminium plates displaying this attractive 'Forest Railway' logo adorned the cabsides and tenders of most C2s, whether or not they operated on forestry lines. We have a range of merchandise featuring this logo, including clothing, badges and replica cast plates.

A11: Here lieth a tale!

In the spring of 2005, Paul travelled to China on an organised tour. Amongst other places, he visited the railway at Dahuichang and saw the C2s in operation there. He enjoyed the visit so much that, upon his return to the UK, he suggested that a return visit should be arranged. This occurred in September 2005, and four of the current C2 Project members took part.

It had not been planned to visit Dahuichang on this occasion, as news of the closure of the line had reached us. However, after we found ourselves in Beijing with a few hours to spare, and after a few phone calls, the staff at Dahuichang kindly agreed to operate a train for us.

During the visit, we told the staff at Dahuichang that several of the group were drivers on the Ffestiniog Railway. Via Dandan, our translator, Mr. Shang joked that since there was no longer a requirement for the C2s at Dahuichang, perhaps we should buy one. It was laughed off as a very silly idea.

That evening, after buying a plentiful supply of beer from the local shops in Beijing, we boarded a sleeper train to our next destination. Before retiring to bed, and with the beer flowing, Mr. Shang's suggestion came up again. Oddly enough, as more beer was drunk the idea didn't seem so silly. And so the seeds of the C2 Project were planted.

We're sure there is a lesson somewhere here about drinking too much beer, but we haven't learned it yet.

中文

中文  Cymraeg

Cymraeg