C2 PROJECT

C2 Technical Data

Locomotive Performance

Basics

How fast will it go? What will it pull? These are two of the most frequently asked questions about our C2. At the basic level, the answers are on the technical specification sheet: maximum speed is 35km/h (22mph) and the tractive effort is 3168kgf (6984lbf).

In reality, it's not that simple of course. Your car might be able to achieve 100mph, and it might be able to pull a caravan up a steep hill. But you wouldn't expect it to do both at once, and you would use different gear ratios in each situation. It's the same with steam locos; there is a trade-off between speed and 'tractive effort' (the force it pulls with).

There are three main factors that limit what a steam loco can achieve:

- The power output of the boiler, expressed in the rate at which it can evaporate water into high-pressure steam. This depends on factors like the boiler dimensions and efficiency, and the heat produced by the fire. The driver can open the regulator wide but ultimately the steam supply is limited by how fast the water is boiled. (It's worth noting that the boiler is also a steam reservoir, so for short periods the driver can use more steam than is being produced and 'mortgage' the boiler - it has to be paid back later).

- The valve gear setting, expressed as the cut-off. At low speed, steam is admitted for up to 70% of the piston stroke, giving sustained high torque. At higher speeds, the steam is cut off earlier in the stroke (maybe 30%), and it expands for the remainder of the stroke. This is more efficient but gives lower average torque. The valve gear cut-off setting is equivalent in function to the gears on a car.

- The wheel/rail adhesion levels. On slippery rails the wheels will just spin if the loco tries to put down too much power. This is influenced by the weight on the driving wheels and the friction coefficient.

The condition of the loco can also have a big influence. If the valve gear or piston rings are worn, or steam is leaking, then performance will be compromised. For now, we'll just consider the performance of a well-maintained loco.

C2 Performance Characteristics

As explained elsewhere on this website, the C2 is a development of the Russian PT-4. Although the Chinese made several modifications to cab shapes, regulator positions, coupling rods etc, the basic dimensions of boiler, cylinders, motion and wheels are unchanged. We found two similar graphs showing the PT-4 performance; these should also be accurate for the C2:

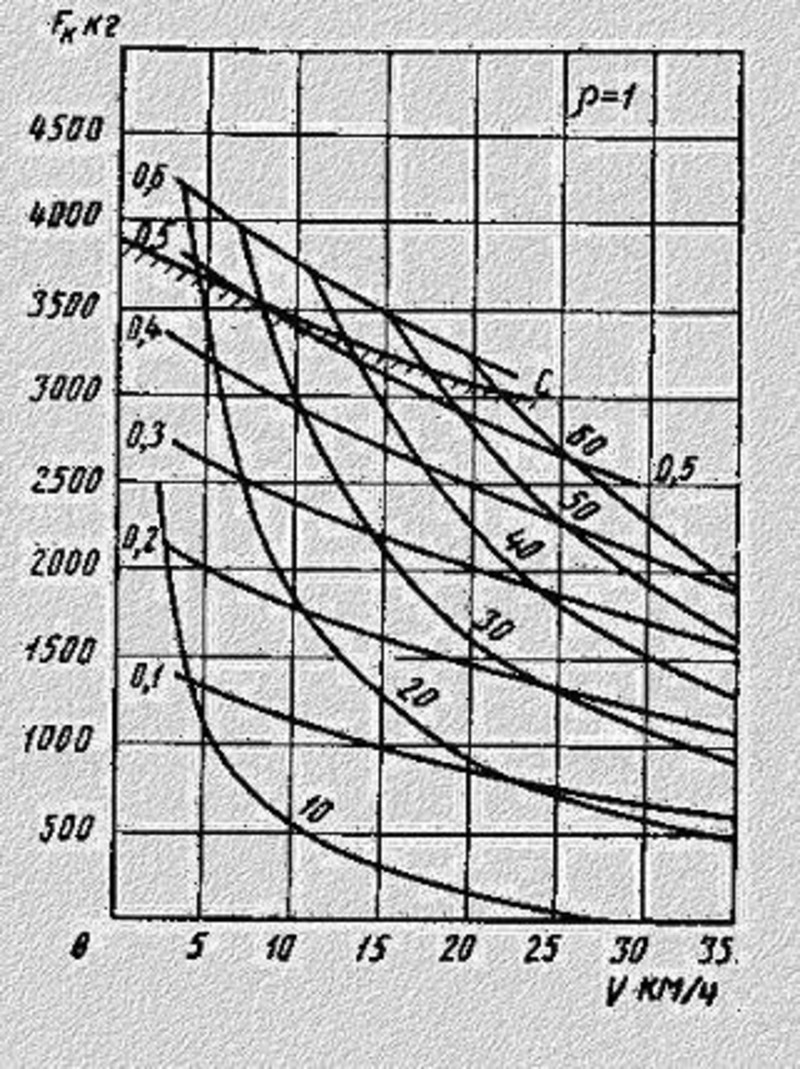

Performance Characteristics for the Russian PT-4, from a Russian-language book - these should also be applicable to the C2. From: http://uzd.spb.ru/parovoz2.htm

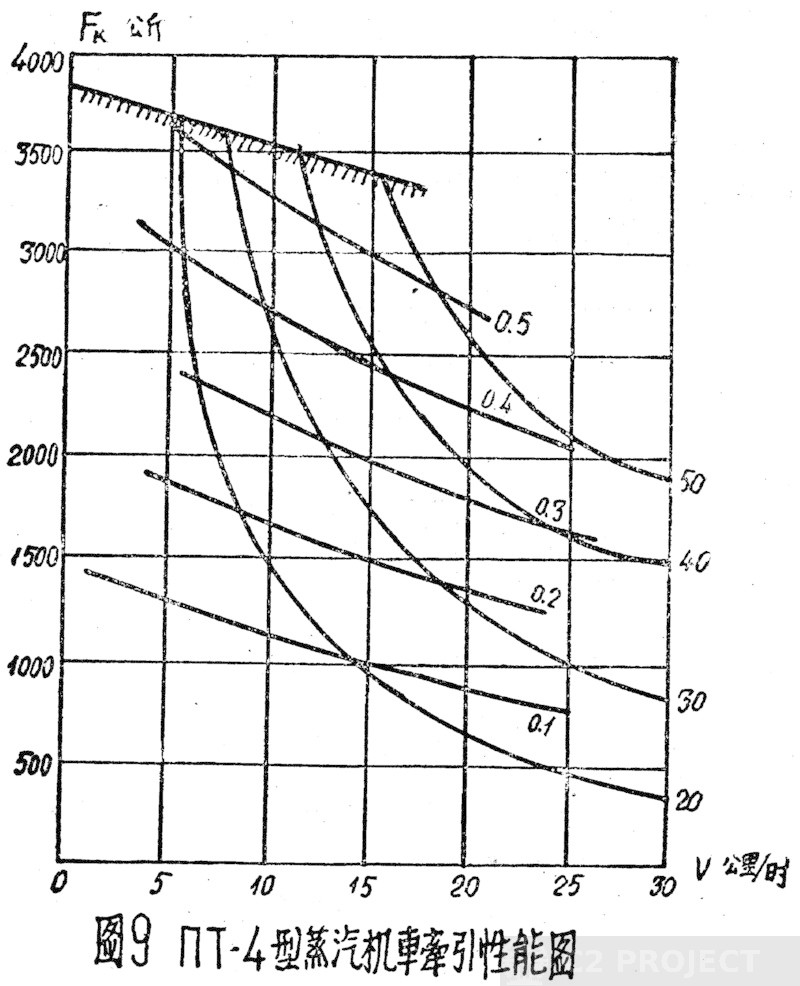

A similar graph for the Russian PT-4, scanned from a Chinese manual on narrow-gauge railways dated 1957. By this time the Chinese were operating similar KP-4 and KV-4 locos, but had not yet started building their own C2 copies.

It's so covered in lines, it looks like a spider's web - what does it all mean? Actually, it's not that difficult once you appreciate the meaning of each line. It's easier to explain on this coloured version:

Across the bottom is speed in km/h, zero up to 35km/h the maximum speed of the C2. Maximum line speed on the FR and WHR is 20mph = 32km/h, marked by the dotted line.

Up the side is the tractive effort: this is how hard the loco can pull. It's expressed in kgf - the force needed to lift a kilogram. So at slow speeds the loco could pull hard enough to lift 3000kg (3 tonnes) vertically, or more realistically 300 tonnes on a 1:100 gradient.

The red lines represent the valve gear cutoff. A long cutoff (0.6=60% at the top) is great for torque but no good at high speed. Shorter cutoffs (0.2=20%) are great for speed and efficiency but don't pull so hard.

The blue lines represent the steaming rate of the boiler needed to supply power to the cylinders. At a steam output of 20, the loco can pull hard at walking pace, or it can race away without a train. To pull a heavy train at top speed needs a boiler steam output of 60. That's a lot more coal for the fireman to shovel.

We think the yellow line near the top represents the limit of adhesion. In simple terms this should be a horizontal line, but there are effects that could reduce it at higher speeds. Both torque and vertical wheel load can vary dynamically which could reduce the adhesion limit; perhaps the Russians have included these in their calculations. The co-ordinates of this line imply a coefficient of friction of 0.24 at zero speed, which is reasonable.

The purple line is the nominal tractive effort quoted on the C2 specification sheet. This appears to have been calculated from the traditional equation, using an efficiency factor of 0.6, and gives a value typical of the loco performance at a range of speeds. In the UK, an efficiency factor of 0.85 was more commonly used: this would give a value of 4574kgf which is close to the maximum tractive effort that a C2 could achieve when starting on a dry rail.

Tractive Effort = c•P•d²•s / D

c = efficiency factor

P = boiler pressure

d = piston diameter

s = piston stroke

D = driving wheel diameter

P = boiler pressure

d = piston diameter

s = piston stroke

D = driving wheel diameter

Loco Performance on the Ffestiniog Railway

All those lines and numbers are all very well, but what does it mean for the C2's performance. Well, there have been some tests and calculations carried out for several FR locos in the past, and we can use that data to put the C2 performance into context.

The ruling gradient of the FR is 1 in 80, which means that to haul a train at constant speed uphill needs a tractive force of 12.5kgf/tonne just to overcome gravity. Additionally there is the rolling resistance of the train (axle bearings, wheel/rail friction in curves etc). FR test data suggests this averages approximately 5.5kgf/tonne. So for a given train weight (loco+coaches) we can estimate the tractive effort needed to maintain speed uphill.

The 1:80 gradient on the FR is sustained for several miles between stations, so the locos must be able to deliver continuous performance while maintaining the boiler pressure and water levels. A very gradual decline in boiler water level on the run can be tolerated if it is made back up at station stops.

The graph below is on exactly the same axes as the previous one. It shows the calculated limiting tractive effort for the diesel 'Upnor Castle'. It also shows the maximum 'envelope' of tractive effort for steam loco 'Blanche' derived from dynamometer tests. Both locos are of similar weight (16 tonnes). The horizontal lines indicate the theoretical tractive effort needed to maintain speed uphill with loco plus 6 carriages and loco plus 8 carriages.

Look where the 'Blanche' line crosses the '8 carrs' line - it's about 30km/h = 19mph. This suggests that Blanche can haul 8 carriages at 19mph, which is about right. In practice it can do 20mph with that load, but not while maintaining water level in the boiler (remember that the tractive effort at high speed is limited by the steaming capacity of the boiler). 18mph is a more typical speed with a full 8-carr load.

Look where the 'Upnor Castle' line crosses the '6 carrs' line - it's about 25km/h = 16mph. That's about right for the noisy 'Uproar', it will just manage 17mph with that load in practice.

C2 Performance on the Ffestiniog Railway

The next graph shows the C2 performance (as before) and overlays the tractive effort needed to maintain speed uphill for various lengths of train, including the 28 tonne weight of the C2. These are shown in light green, for trains of loco plus 6, 8, 10, 12 carriages. Also included is the result from the tests on 'Blanche' as a comparison.

Let's consider a train of 10 carriages, which is a common train length throughout the year on the FR. To haul this at line speed (20mph) we're near the limit of the C2 characteristic. The C2 would be in a cutoff of 45% and with a boiler steaming rate about 65.

Is this reasonable? Well the 'running notch' on the Blanche is about 50% cutoff, and on the double Fairlies it's about 35%. So 45% is quite plausible.

Looking at the steaming performance of the Blanche on test, it's a achieving about 45 (the curved part of the dark green line lies between the blue lines marked 40 and 50). The C2 has twice the grate area of the Blanche, and the boiler volume and heating area are also much larger. A steaming rate of 65 for the C2 should be straightforward with the good quality coal we have on the FR.

So it appears that the C2 should be capable of hauling a 10-carr train at 20mph on the FR. Longer trains of 11 or 12 carriages should be within its haulage capacity at reduced speed - around 17mph - but adhesion might be a problem on wet days.

C2 Performance on the Welsh Highland Railway

What about the Welsh Highland? The gradients are twice as steep (1:40) and sustained for several miles, and the carriages are a little bigger and heavier. Experience with existing Ffestiniog locos running on the Welsh Highland is that they can pull about half the number of carriages.

The graph below confirms this: the tractive effort needed to haul 5 carrs on the WHR is very similar to that needed to haul 10 carrs on the FR:

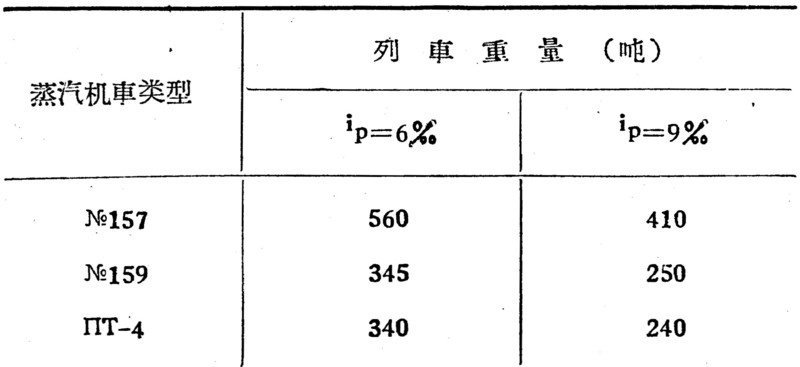

The Russian and Chinese narrow gauge railway design manuals seem to have assumed that the railways would be rather gently graded - the haulage capacity for the locos is quoted on gradients of 1 in 167 (6‰) and 1 in 111 (9‰).

. The maximum train load for the PT-4 on the 9‰ gradient is 240 tonnes - about twice as much as the heaviest trains we run on the FR! Of course, the speed would be low with such a heavy train.

. The maximum train load for the PT-4 on the 9‰ gradient is 240 tonnes - about twice as much as the heaviest trains we run on the FR! Of course, the speed would be low with such a heavy train.

Maximum haulage capacity of the PT-4, taken from a Chinese manual on railway design; the C2 should be capable of the same performance.

Conclusion

On the FR, the C2 should be capable of reliably hauling 10 carriages at 20mph, making it a useful locomotive all year round. It could manage an 11 carriage train at about 18mph, which is sufficient to maintain the timetable. Adhesion could be a limitation on longer trains in wet weather.

On the WHR, the C2 should be capable of reliably hauling 5 carriages at 20mph, and 6 carriages would be possible at 17mph in dry conditions. Adhesion limits would prevent the loco hauling longer trains on the steep gradients.