C2 PROJECT

C2 Photo Album

album:September 2022

Slots cut in the smokebox saddle, ready for mounting to the frames. It has also now been cleaned up and painted inside and out.

Initial setup for the extractor fan ducting on the firebox.

Notch in the smokebox saddle to fit between the cylinder ribs.

James cleans up one of the diaphragm plate spacers.

Slots in the smokebox saddle marked out for cutting.

The boiler moved backwards on the wagon to give better access to the inner firebox and the smokebox saddle.

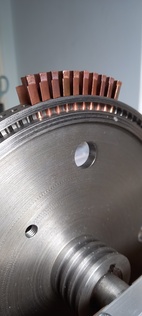

The first 10 turbine blades fitted; there are 110 in total.

One of the old governor weights which Erle is now replacing.

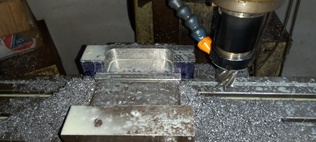

Stages in machining the replacement governor weights, which are a remarkably complex shape!

Stages in machining the replacement governor weights, which are a remarkably complex shape!

The old boiler after Andrew, Jake and Jacinta had cleaned and painted it prior to the main working party.

The old boiler after Andrew, Jake and Jacinta had cleaned and painted it prior to the main working party.

Breathing equipment has arrived for use while cleaning the inner firebox.

The profile for the rear diaphragm plate, showing how it is positioned in the frames.

Bobby drills the bolt holes in the diaphragm plate and its spacer.

The diaphragm plate drilled and ready for final cleaning, painting and fitting.

Paul removes slag from the underside of the smokebox saddle after cutting the slots.

James hoovers out the smokebox while Paul cleans the underside of the smokebox saddle.