C2 PROJECT

C2 Photo Album

album:November_2022

The TIG-welded joint in the turbine retaining band

Stages in machining the complex shape of the turbine governor weights.

Stages in machining the complex shape of the turbine governor weights.

Stages in machining the complex shape of the turbine governor weights.

Governor installed on the turbine disc.

The completed governor weights, compared to the damaged originals

The refurbished original cab steps.

The completed cab floor frame placed in position.

The cab floor outer frame trial-fitted to the loco frame after tack welding.

Trial fitting of the piston into the bore from the front

Helen and Paul straighten the cab steps with by localised heating with the oxy-acetylene.

Andrew has set out the basic cab floor frame to tack weld it together. This was then offered up to the loco frames to ensure that it was correct. Remember, measure twice, cut once!

Welding in the intermediate ribs which will support the floorboards.

Here is the cab floor in place on the loco frames. The floor boards will be placed over this frame. Note one of the original cab steps, temporarily clamped in place.

Yabuli Forestry Railway 06 hauls a train of logs and brushwood in 1998. Photographer unknown, original slide purchased by Paul.

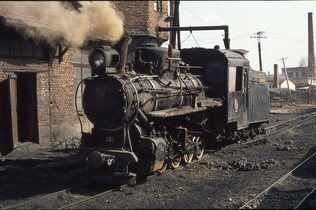

Yabuli Forestry Railway C2-161 at the stabling point in 1998. We believe this is Harbin works number 161. If so, it was built in 1963, the last loco of Harbin's first (large) batch of C2s. New C2 production at Harbin resumed in 1975. Photographer unknown, original slide purchased by Paul.