C2 PROJECT

C2 Photo Album

album:May Day 2019

Andrew`s first attempt at welding Chinese text (or indeed any text). Andrew thinks a bit more practice will be needed before welding the treads on the loco and tender steps. This is the Mandarin character for Safety - May 2019

Completed tender handbrake linkages. The slots allow the brakes to be actuated independently by the steam brake cylinder. - Paul Molyneux-Berry, May 2019

Tender brake pull rods welded up by Andrew. - Paul Molyneux-Berry, May 2019

Dave machining holes in the tender brake linkages. - Paul Molyneux-Berry, May 2019

Moving the motion brackets to the Radial Arm Drill in the erecting shop - Paul Molyneux Berry, May 2019

Dave drilling out holes on the tender brake linkages - Paul Molyneux-Berry, May 2019

Matt and Alan drilling holes in the motion brackets - Paul Molyneux-Berry, May 2019

A view showing the misalignment between the top and bottom holes on the motion brackets - Paul Molyneux Berry, May 2019

Alan and Matt setting up the motion brackets on the radial arm drill - Paul Molyneux Berry, May 2019

Dave drilling out holes on the tender brake linkages - Paul Molyneux-Berry, May 2019

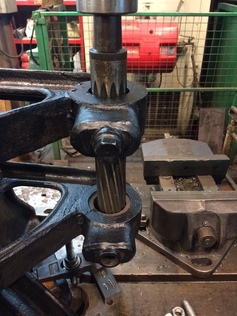

Alan machining the slotted link profiles on the Bridgeport milling machine - Paul Molyneux-Berry 2019

Alan machining the slotted link profiles on the Bridgeport milling machine - Paul Molyneux-Berry 2019

Front and rear crash beam brackets in progress on the bench - Andrew Nelms, May 2019

Tender rear crash beams trial mounted on the rear of the tender - Andrew Nelms, May 2019

Front crash beam brackets on the band saw being trimmed to the correct shape - Andrew Nelms, May 2019

Front crash beam brackets drilled and marked up ready for cutting - Andrew Nelms, May 2019

Three Fairlie locomotives on Saturday morning at the start of a very busy day on the Railway! - Andrew Nelms, May 2019