C2 PROJECT

C2 Photo Album

album:Late May 2023

White-tailed Bumblebees nesting in an old sleeper outside our shed.

View of Snowdon and Cnicht on a sunny May morning, from the Cob near Boston Lodge.

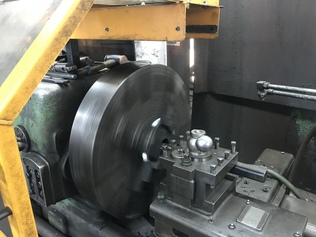

Setup for drilling and reaming the sleeve holes in the Vesconite split bearings for the tender brake weighshaft.

Paul drilled the assembly in stages to a 2" diameter.

Then a large boring bar was used to enlarge the hole to the required size of 59.1mm.

Split bearing with machining complete. We made two of these.

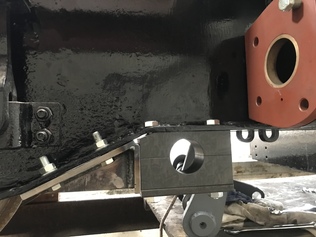

Tender brake weighshaft split bearing mounted on the tender frame, with the reaction bracket being trial-fitted. The red part is the end of the steam brake cylinder which acts on a crank at the outer end of the weighshaft.

Centering the split bearing in the 4-jaw chuck, ready for boring the main bearing.

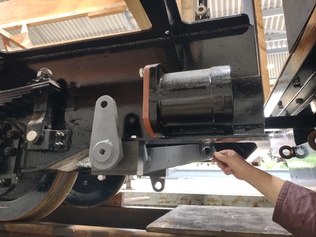

Tender brake weighshaft trial-mounted to check that everything aligned correctly. It did!

Tender brake weighshaft trial-mounted to check that everything aligned correctly. From left to right, the cranks will attach to: steam brake cylinder, return spring, hand brake, and the pull rod to the brake gear.

Alan welds up the inner brake reaction bracket.

Tender brake weighshaft trial-mounted to check that everything aligned correctly. It did!

Paul prepares to lift the weighshaft and its brackets into position. Dave 2 was positioned above at the top of the rope, to take the weight while Paul inserted the bolts.

The C2 positioned over the carriage inspection pit for trial assembly of the tender brake gear.

Dave 2 and Paul position the outer reaction bracket.

The completed tender brake weighshaft.

One of the Welsh Highland trains had ended up stranded at Beddgelert overnight, and Andrew assisted in transporting the crew and loco preparation supplies to Beddgelert early in the morning. Steam was raised while the train was dragged back to Porthmadog with the Funkey diesel. All was ready for the booked departure.

Special boring bar being manufactured by Erle for one of the last machining tasks on the Turbogenerator.