C2 PROJECT

C2 Photo Album

album:January 2018

Works train at Minffordd, heading for Moelwyn tunnel.

In the middle of the tunnel, all the track has been removed and the lights of the digger illuminate the 'shotcreted' interior.

Dwarfed by the landscape, the works train stands in tunnel south cutting. We were blessed with fine weather.

Friday dawned clear and bright, but very cold!

These are the castings for our new steam brake cylinders, one each for the loco and tender. They will be completed by the works staff to the same design used on the FR Double Fairlies.

Tender brake gear components laid out for inspection and a review of the work required on each.

The loco brake weighshaft crank was drilled out and reamed to suit a new bush.

One of our tender wheelsets on the big Swift wheel lathe. Andrew concentrates on turning the wheel flange profile. Swift it ain't!

Loco brake components in the paint shop; these are all now finished apart from pressing in the Iglidur bushes.

More completed loco brake components getting a lick of paint.

The brakes have been progressing in the background for months. Hopefully it won't be long before all these parts come together.

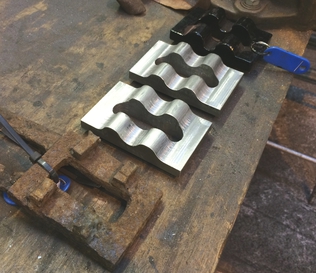

These are the rocking washers for the tender suspension.

More brake links!

A completed tender wheelset. The next task for these is to press on the inner races of the roller bearings, and assemble the axleboxes.

Battery box components assembled into the tender frame, ready for welding.

We trial-fitted the safety chain eyes and their rubber springs.

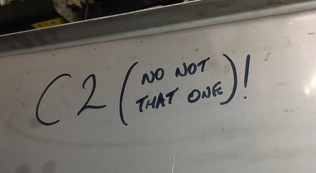

The works staff have been busy building the framework and skin of a new observation carriage. Bob Yates carefully marked all the panels with an alphanumeric code to indicate where they fitted, then realised there was scope for confusion!

Andrew achieved a much better finish after re-arranging the drive to the wheelset being turned.

C2s were built for the winter weather. This is a lovely photo of 028 with a passenger train on the Langxiang Forestry Railway in 1988. This loco was a 1950s Polish-built КП-4 that was later updated to late C2 specification at Harbin works.

Erle's completed rocking washers for the tender suspension, compared to a good original.

There's a fire inside her, but Linda's shivering in a hailstorm at dawn on Thursday. Our C2 would be the perfect loco in these conditions.

There was a short break in the precipitation while we took water at Tan-y-Bwlch before heading up to Moelwyn tunnel with a load of fresh ballast. All the diesels were broken!

Andrew positions the front bufferbeam on the horizontal borer.

Brake blocks! We ordered these from South Africa.

Yaw damper brackets, ready for mounting to the rear bufferbeam.

Martin has been machining the castings for our steam brake cylinders, which are looking good.

Paul machined some eyes for the brake gear pull rods.

Alan learns how to use the horizontal borer. We'll need to use this machine again when we re-bore the cylinders and valves.

Dave 1 uses the horizontal borer to enlarge the slot in the front bufferbeam.

Instead of the usual view of Snowdon from our works, here’s a look in the other direction: out to sea over the Traeth Mawr. After several wet days, we had a beautiful sunset on Saturday evening.

More brake gear pull rod machining, on the Wanderer mill.

Erle puts the finishing touches to the spring rocker washers, on the Bridgeport mill.

Colin trues up the spigot on the end of the handbrake column, using the big Colchester lathe. He also made a stainless steel sleeve to fit over the spigot.

Colin machined and sleeved the handbrake column nut - we're making a good start on the tender brake gear now.

Dave 2 machined these two spigots. They will be used as a jig for setting up the brake hangers for machining their holes to size.

Counter-boring the rear bufferbeam, so that the safety chain eyes can be recessed into it.

Tender spring rocking washers. The nearest one deserves to go in the 'rogues gallery' of Chinese bodges! Erle's new ones are much nicer.