C2 PROJECT

C2 Photo Album

album:February 2020

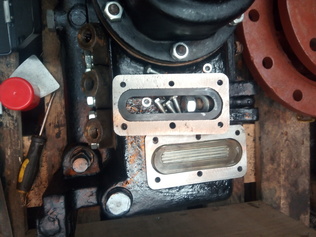

Assembly of refurbished pump units into the spare lubricator.

All the pumps now fitted.

Fitting the strainer into the enlarged holes.

With the lid fitted, the third (spare) lubricator is nearing completion.

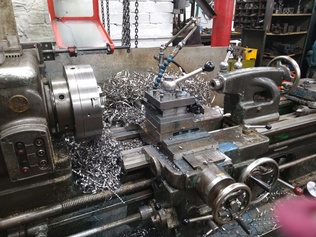

Dave 1 made a lot of swarf! (don't worry, we did clean it all up afterwards)

A collection of pins and collars for the brake gear, made by Andrew and both Daves.

Trial assembly of brake hanger with brake block carrier and composite block. With brand new wheels and blocks, clearances are the tightest they will be in the loco's life.

As well as several pieces of steel for brake gear and some tooling, we received these pieces of Vesconite which will soon become the bearings for the reverser weighshaft and expansion link.

Porthmadog harbour with the water over-topping the walls. Note the quayside fences surrounded by water! A combination of low air pressure, high tide, strong wind from the sea and heavy rain coming down the river caused this extreme water level. Fortunately this was the highest it got, and the only building getting damp was the harbour master's office.

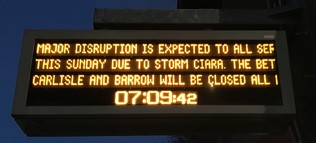

Looking out across the cob, with waves breaking over the embankment. Boston Lodge in the distance is obscured by the heavy rain of Storm Ciara.

New piston rod for the loco steam brake cylinder, machined from a rectangular block by Paul.

Many of us had challenges getting home! Hopefully the forthcoming Storm Dennis will have passed by the time of our next working party.

Thursday had some bright moments with a bit of sun, but the Traeth Mawr was filling up. A touch of snow on the top of Snowdonia.

Remachining the coupling rod knuckle joints. The first stage was to enlarge the hole in one side of the fork.

And the second stage was to use a tapered reamer to ream both holes to the same taper.

Dave and Scott mark out the holes we drilled in the steam brake cylinder mounting flanges.

Friday and Saturday saw continued heavy rain, until the Cob was fully surrounded by water on both sides.

Erle checks the dimensions of the special nuts he made for the lubricator steam heat pipe.

The steam brake cylinder set up for drilling. Dave also machined the rebate visible on the end, so that there is a true flat face we can butt up against a thrust block.

The steam brake cylinder, piston and crank temporarily mounted to check clearances.

These new covers will fit on the redesigned coupling rod knuckle joints, to retain the new tapered pins. They are designed to match the adjacent roller bearing covers.

Here's a knuckle joint cover positioned on a one of the coupling rod forks.

New brake pins machined by Dave

New lubricator steam heating pipe and end fittings made by Erle.

Refurbished lubricator sight glass bezel with new packer plate machined by Erle.

The sight glass in position and painted.